As global businesses reassess their sourcing strategies in 2025, OEM manufacturing in Vietnam has become a top consideration. While Vietnam is known for its low-cost labor, the country now offers more than just affordability. From flexible production volumes to advanced customization and export efficiency, Vietnam is redefining the value of OEM partnerships. But is it truly worth it?

Vietnam’s Competitive Labor Costs in OEM Manufacturing

Labor remains one of the most influential cost components in manufacturing, particularly for labor-intensive sectors. In 2025, Vietnam’s average minimum wage is approximately $0.76 per hour, according to World Population Review. This is around 40% lower than China’s rate of $1.27 per hour, creating a significant cost differential that directly reduces the total cost of production.

This wage gap is especially impactful for industries like furniture, garments, electronics, and electrical panels, where labor accounts for a large portion of unit costs. OEM manufacturers in Vietnam capitalize on this by offering more competitive pricing while maintaining consistent production quality. Lower wages don’t equate to lower standards—factories in Vietnam often combine skilled labor with lean manufacturing processes to meet international expectations.

For global brands seeking to optimize profit margins, serve price-sensitive markets, or improve cost-efficiency without sacrificing quality, this labor advantage is a key reason to move or diversify production to Vietnam. When paired with favorable trade agreements and efficient logistics, Vietnam’s labor structure provides a sustainable foundation for OEM partnerships in 2025 and beyond.

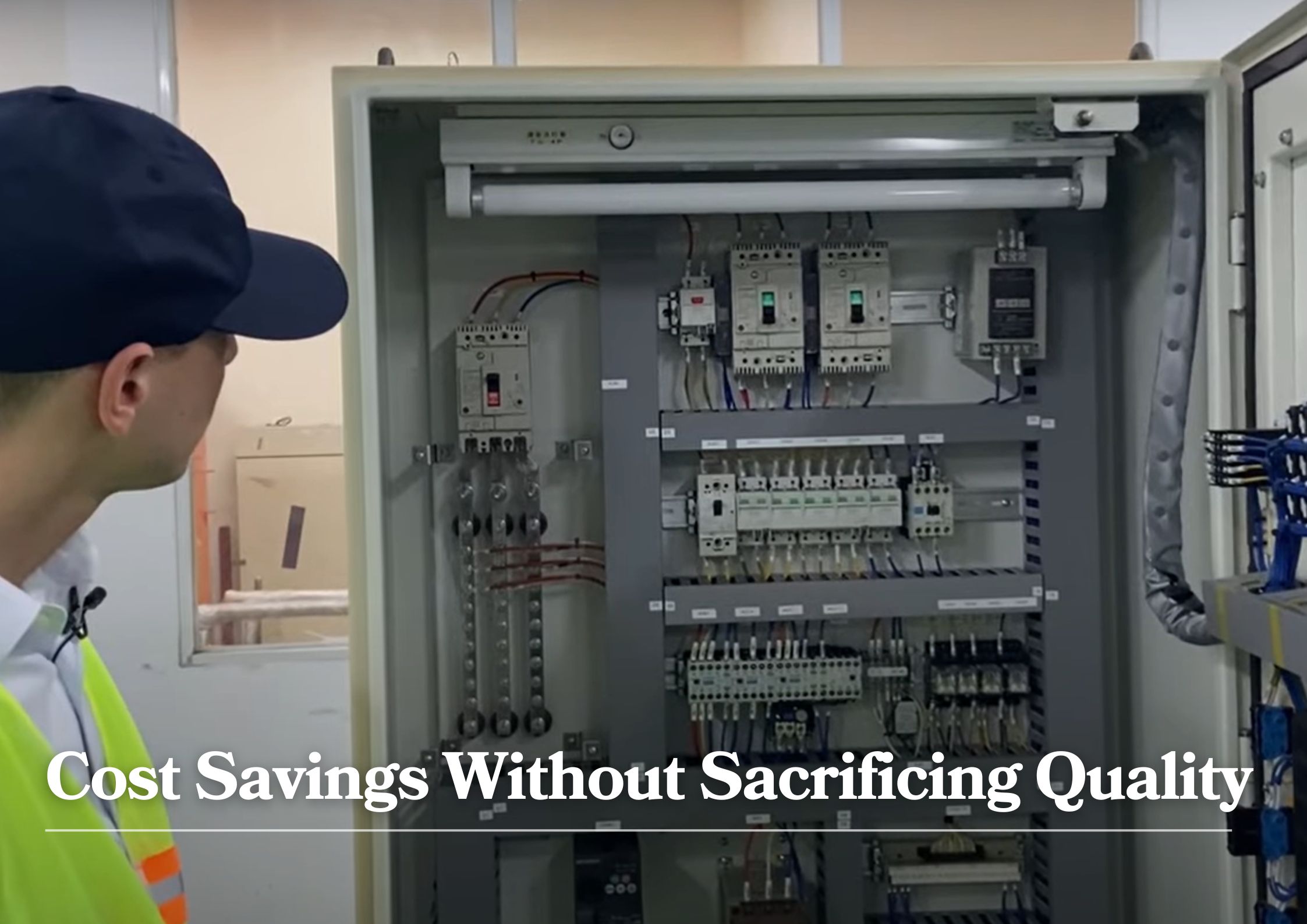

In this video, we visit an OEM factory in Binh Duong that specializes in producing electrical panels and sheet metal parts for export. Watch to discover the production capabilities of OEM factories in Vietnam and understand why the country is becoming a competitive hub for custom manufacturing.

Low Overhead Keeps Vietnam’s OEM Total Costs Competitive

Beyond labor, overhead expenses such as industrial rent, energy, and regulatory compliance play a crucial role in determining the true cost of manufacturing. In this regard, Vietnam continues to outperform many of its Asian peers. According to the 2025 Waypoint: Global Industrial Dynamics Report by Cushman & Wakefield, Vietnam ranks as one of the most cost-competitive countries for industrial and logistics investment worldwide.

Despite sharp growth in recent years, average industrial rents in key manufacturing hubs like Ho Chi Minh City and Hanoi remain affordable—around $4.9 to $5.3 per square meter per month. These rates are significantly lower than those in China, India, and even parts of Southeast Asia. Electricity costs also remain among the lowest globally, second only to countries like Indonesia and Nigeria, which further reduces operating expenses for OEM factories.

Logistics and Transportation Costs in OEM Manufacturing

One important but often underestimated factor in the total cost of OEM manufacturing is logistics and transportation. Vietnam enjoys a strategic geographic position in Southeast Asia, located near major international shipping routes. This makes it easier and more cost-effective for businesses to access key export markets such as the United States, the European Union, Japan, and South Korea, with shorter lead times and reduced shipping costs.

Vietnam also benefits from a long coastline of over 3200 kilometers, supporting the development of a comprehensive seaport system stretching from north to south. Many OEM factories in Vietnam are strategically located near major port hubs such as Hai Phong, Da Nang, and Cai Mep Thi Vai. This proximity helps streamline the transportation journey from factory to port, shortening order processing times, minimizing domestic logistics costs, and accelerating export delivery to international markets.

In addition, the rapid development of transport infrastructure from highways to centralized industrial zones has made logistics more flexible and efficient. Combined with open export policies and improved customs procedures, Vietnam is emerging as an ideal destination for global brands seeking to optimize supply chain costs while maintaining speed and reliability in delivery.

Cost Savings Without Sacrificing Quality

One of the most compelling aspects of OEM manufacturing in Vietnam is the balance between cost savings and quality assurance. While lower labor and overhead costs drive competitiveness, they do not come at the expense of product standards. Many Vietnamese OEM factories operate under international certifications such as ISO 9001, ISO 14001, and UL standards—ensuring compliance with strict quality, safety, and environmental benchmarks.

Factories often invest in modern machinery, quality control systems, and skilled engineering teams to meet the specific requirements of global clients. For industries like electrical panels, sheet metal fabrication, and electronics, this means reliable performance, precise customization, and reduced defect rates—even in large-volume production.

Moreover, foreign direct investment (FDI) and technology transfer from established brands have contributed to the maturity of Vietnam’s manufacturing ecosystem. As a result, buyers benefit from cost-effective production that still meets the technical, visual, and regulatory demands of their end markets. This quality-cost balance makes Vietnam a preferred destination for brands seeking to reduce expenses while upholding product integrity.

Final Thought: Is Vietnam OEM Manufacturing Worth It in 2025?

In today’s competitive and rapidly shifting supply chain landscape, OEM manufacturing in Vietnam presents a compelling opportunity for global brands. With lower labor and overhead costs, strategic export advantages, and a growing ecosystem of certified factories, Vietnam delivers more than just savings, it offers a balanced, scalable, and high-quality solution for custom production.

As brands look beyond traditional hubs like China, Vietnam stands out not only for its affordability but also for its ability to meet international standards and adapt to diverse production needs. Whether you’re sourcing electrical panels, metal parts, electronics, or furniture, the country offers real value across the entire OEM lifecycle.

For businesses seeking to reduce costs without compromising on quality, flexibility, or speed, Vietnam is no longer just an alternative, it’s a strategic choice in 2025 and beyond.